The content of this article is mainly divided into three parts:

1. Classification of fasteners

2. Thread identification and inspection

3. Material requirements, heat treatment requirements and mechanical performance requirements for bolts, screws and studs

4. Types and construction of steel structural bolts

First, the classification of fasteners

What is a fastener and what is the meaning of the fastener?

1. What is a fastener? A fastener is a general term for a type of mechanical part used to securely join two or more parts (or components) into one unit. The market is also known as standard parts.

2. It usually includes the following 12 types of parts:

Bolts, studs, screws, nuts, self-tapping screws, wood screws, washers, retaining rings, pins, rivets, assemblies and joints, welding studs.

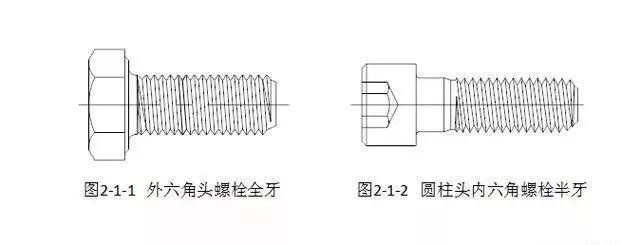

2.1) Bolt: A type of fastener consisting of a head and a screw (a cylinder with an external thread), which is to be fitted with a nut for fastening two parts with through holes. This type of connection is called a bolted connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection.

As shown below:

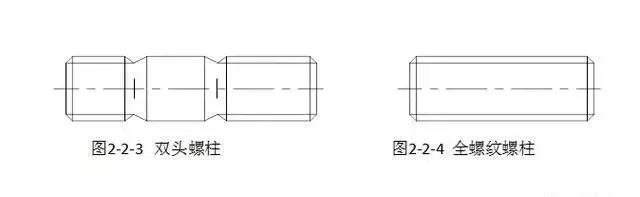

2.2) Stud: A type of fastener that has no head and only has threads on both ends. When connecting, one end must be screwed into the part with the internally threaded hole, the other end is passed through the part with the through hole, and then the nut is screwed, even if the two parts are fastened together. This type of connection is called a stud connection and is also a detachable connection. It is mainly used in the case where one of the connected parts has a large thickness, requires a compact structure, or is frequently used for disassembly, and should not be bolted.

As shown below:

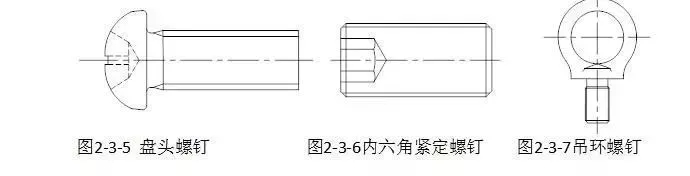

2.3) Screw: A type of fastener consisting of two parts, the head and the screw. It can be divided into three categories according to the application: steel structure screws, set screws and special purpose screws. The machine screw is mainly used for a tightly threaded part and a tight connection with a part with a through hole. No need for a nut fit (this type of connection is called a screw connection and is also a detachable connection; Fitted with a nut for a secure connection between two parts with through holes.) The set screw is primarily used to secure the relative position between the two parts. Special purpose screws such as eyebolts are used for lifting parts.

As shown below:

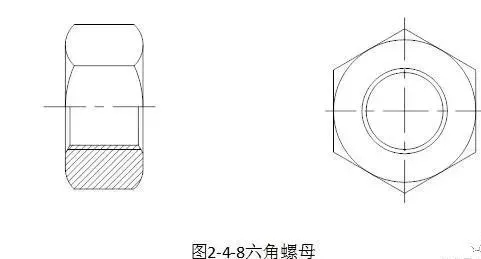

2.4) Nut: With internal threaded hole, the shape is generally flat hexagonal column shape, but also has a flat square column or a flat cylindrical shape. It is equipped with bolts, studs or steel structure screws for fastening two parts. Make it a whole.

As shown below:

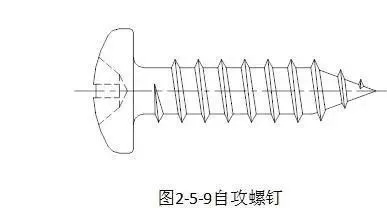

2.5) Self-tapping screws: Similar to screws, but the threads on the screw are dedicated self-tapping screws. It is used to fasten and connect two thin metal members to make them integral. The holes need to be made in advance on the members. Since the screws have high hardness, they can be directly screwed into the holes of the members. Form the corresponding internal thread. This form of connection is also a detachable connection.

As shown below:

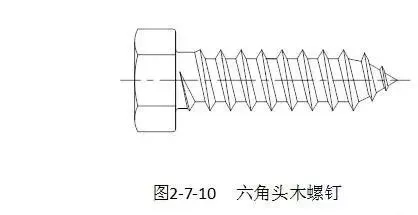

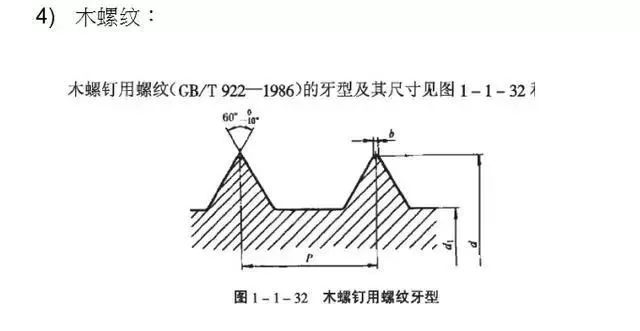

2.6) Wood screws: also similar to screws, but the threads on the screw are special wood screw threads that can be screwed directly into the wooden component (or part) for a metal (or non-metallic) part with a through hole. Fastened to a wooden component. This connection is also a detachable connection.

As shown below:

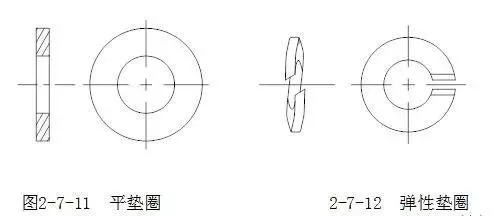

2.7) Washer: A type of fastener that is oblate in shape. Between the support surface of the bolt, the screw or the nut and the surface of the connecting part, it increases the contact surface area of the connected part, reduces the pressure per unit area and protects the surface of the connected part from damage; another type of elastic washer, It also acts to prevent the nut from loosening.

As shown below:

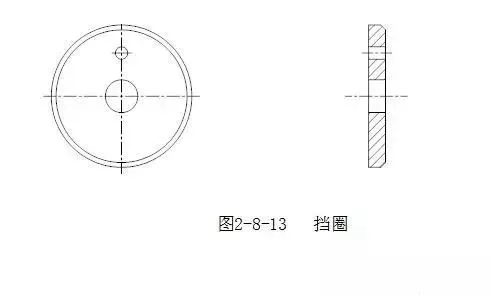

2.8) Retaining ring: It is installed in the shaft groove or hole of the steel structure and equipment, and plays the role of preventing the left and right parts of the shaft or the hole from moving.

As shown below:

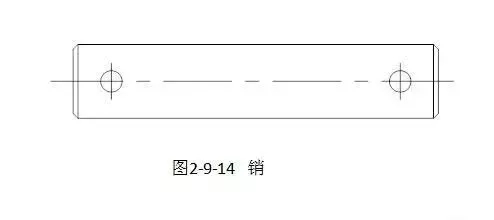

2.9) Pin: It is mainly used for part positioning, and some can also be used for connecting parts, fixing parts, transmitting power or locking other fasteners.

As shown below:

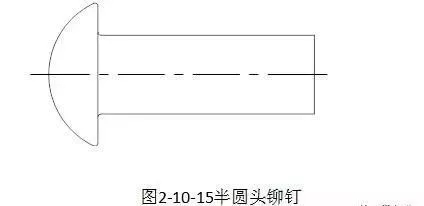

2.10) Rivet: A type of fastener consisting of two parts, the head and the shank, used to fasten the two parts (or components) with through holes to make them integral. This type of connection is called a rivet connection, referred to as riveting. It is a non-detachable connection. Because the two parts that are joined together are to be separated, the rivets on the part must be destroyed.

As shown below:

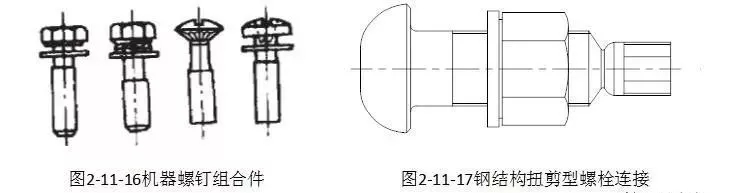

2.11) Assembly and connection pair: The assembly refers to a type of fastener supplied in combination, such as a combination of a certain machine screw (or bolt, self-supply screw) and a flat washer (or spring washer, lock washer); A pair of fasteners that supply a combination of special bolts, nuts, and washers, such as high-strength large hex head bolts for steel structures.

As shown below:

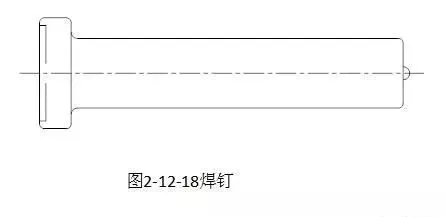

2.12) Solder Stud: Due to the heterogeneous fastener consisting of the polished rod and the nail head (or the nailless head), it is fixedly attached to a part (or component) by welding to connect with other parts.

As shown below:

Second, the identification and inspection of the thread

1, the use and characteristics of the thread:

Threads are used in a wide variety of applications, from airplanes and cars to water pipes and gas used in our daily lives. Most of the threads play a role in tightening the connection, followed by the transmission of force and motion. There are also some special-purpose threads, many of which are limited in number.

The use of the thread can last for a long time because of its simple structure, reliable performance, easy disassembly, and easy manufacturing. It has become an indispensable structural element in various electromechanical products.

According to the use of the thread, all kinds of threaded parts should have the following two basic functions: one is good screwing; the other is sufficient strength.

2, the classification of the thread

a, according to its structural characteristics and uses can be divided into four categories:

Ordinary thread (fastening thread): The tooth shape is a triangle for connecting or fastening parts. Ordinary threads are divided into coarse teeth and fine thread according to the pitch, and the connection strength of the fine thread is high.

Drive thread: The shape of the tooth is trapezoidal, rectangular, saw-shaped and triangular.

Sealing thread: used for sealing connection, mainly for pipe thread, taper thread and taper pipe thread.

Special purpose thread, referred to as special thread.

b. According to the region (country), the thread can be divided into: metric thread (metric thread) inch thread, American thread, etc. We used to refer to the inch thread and the US thread collectively as the inch thread, and its tooth angle is 60°, 55°. Etc., the diameter and pitch and other related thread parameters are in inch size (inch). In our country, the angle of the tooth is unified to 60°, and the diameter and pitch series in millimeters (mm) are used to name the thread: ordinary thread.

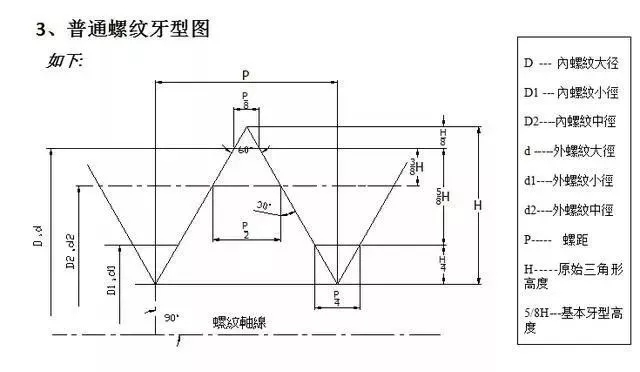

4, the basic terminology of the thread

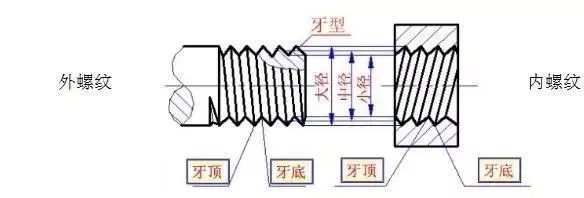

Thread: A continuous protrusion with a defined tooth shape formed along a spiral on a cylindrical or conical surface.

External thread: A thread formed on the outer surface of a cylinder or cone.

Internal thread: An internal thread formed on the inner surface of a cylinder or cone.

Large diameter: The diameter of an imaginary cylinder or cone that is tangent to the root of the external thread or internal thread.

Trail diameter: The diameter of an imaginary cylinder or cone that is tangent to the crest of an external thread or internal thread.

Middle: The diameter of an imaginary cylinder or cone that passes through the groove and the width of the projection on the tooth. The imaginary cylinder or cone is called a medium diameter cylinder or a medium diameter cone.

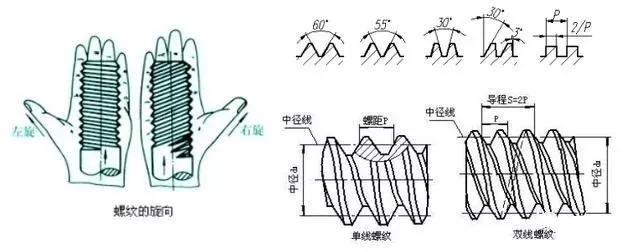

Right-hand thread: A thread that is screwed in when rotated clockwise.

Left-hand thread: A thread that is screwed in when rotated counterclockwise.

Tooth angle: The angle between two adjacent flank on the thread profile.

Pitch: The axial distance between two points on the middle diameter line of two adjacent teeth.

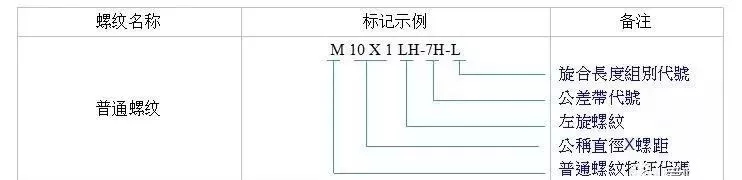

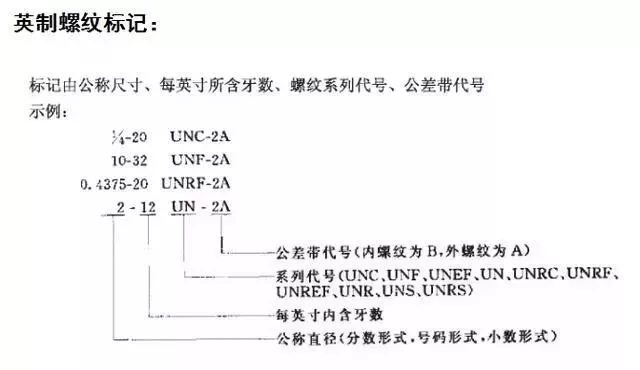

5, the mark of the thread

Metric thread mark:

In general, a complete metric thread mark should include the following three aspects:

a indicates the thread type code of the thread feature;

b Thread size: generally consists of diameter and pitch, for multi-thread threads, should also include lead and line number;

c Thread accuracy: The accuracy of most threads is determined by the tolerance zone of each diameter (including the tolerance band position and size) and the screw length.

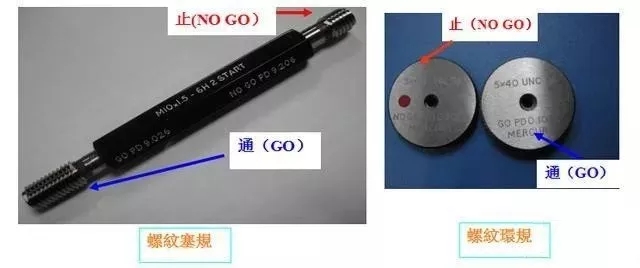

6, thread measurement

For standard standard threads, use a threaded ring gauge or plug gauge to measure.

Due to the large number of thread parameters, it is impossible to measure each parameter of the thread one by one. Usually, we use a thread gauge (thread ring gauge, thread plug gauge) to comprehensively determine the thread. This kind of inspection method belongs to the analog assembly type acceptance method. It is not only convenient and reliable, but also has the same precision requirements as ordinary thread. Therefore, it has become the most common acceptance method in actual production.

7, thread measurement (medium diameter)

In the threaded connection, only the medium diameter size determines the nature of the thread fit, so how to correctly judge whether the middle diameter is qualified is very important. Based on the size of the medium diameter, it should be ensured that the most basic performance of the thread can be achieved. The standard specifies the principle of judging the qualification of the medium diameter, that is: "The actual diameter of the actual thread cannot exceed the diameter of the largest solid tooth type. Actually The single median diameter of any part of the thread must not exceed the median diameter of the smallest solid tooth."

There are two convenient methods for measuring a single medium diameter. One is to measure the median diameter with a threaded diameter micrometer, and the other is to measure with a three-needle method (we use the three-needle method).

8, thread matching level:

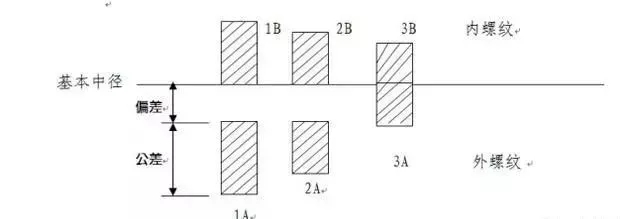

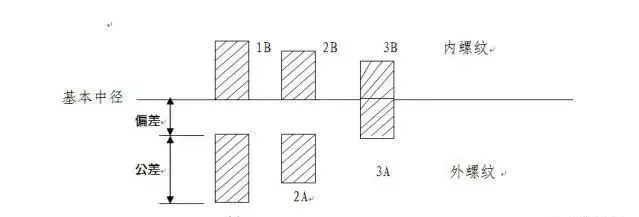

The threaded fit is the loose or tight size between the threaded threads, and the level of fit is the specified combination of deviations and tolerances on the inner and outer threads.

(1) For uniform inch thread, the external thread has three thread grades: 1A, 2A and 3A, and the internal thread has three grades: 1B, 2B and 3B, all of which are clearance fit. The higher the level number, the tighter the fit. In the inch thread, the deviation only specifies the 1A and 2A levels, the 3A level deviation is zero, and the 1A and 2A level deviations are equal.

The larger the number of grades, the smaller the tolerance, as shown:

Class a, Class 1A and Class 1B, very loose tolerance class, suitable for tolerance fits of internal and external threads.

Class b, 2A and 2B are the most common thread tolerance classes specified by the English series of mechanical fasteners.

Class c, 3A and 3B, the tight fit forms the tightest fit for tight tolerance fasteners for critical safety design.

d. For external threads, 1A and 2A have a matching deviation, and 3A does not. The 1A tolerance is 50% larger than the 2A tolerance and 75% larger than the 3A. For the internal thread, the 2B tolerance is 30% larger than the 2A tolerance. Level 1B is 50% larger than 2B and 75% larger than 3B.

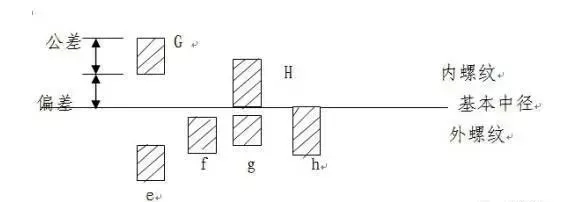

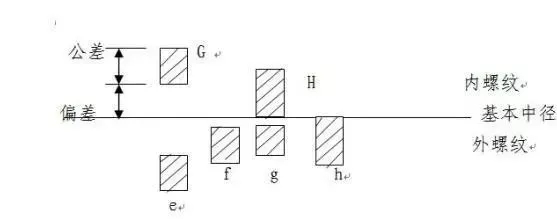

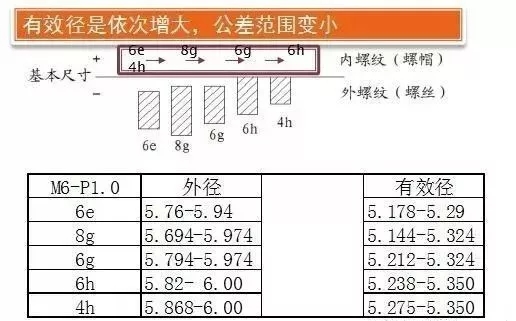

(B), metric thread, external thread has common thread grade: 4h, 6e, 6g and 6h, internal thread has common thread grade: 6G, 6 H, 7H. (The Japanese standard thread accuracy grade is divided into three grades I, II, and III, and the normal grade is grade II.) In the metric thread, the basic deviation of H and h is zero. The basic deviation of G is positive, and the basic deviation of e, f, and g is negative. as the picture shows:

1. H is the common tolerance zone position for internal threads. It is generally not used as a surface coating or an extremely thin phosphating layer. The basic deviation of the G position is used for special occasions, such as thicker coatings, which are rarely used.

2, g is commonly used to plate 6-9um thin coating, such as the product drawing requirements of 6h bolts, the pre-plated thread uses a 6g tolerance band.

3, the thread fit is best combined into H / g, H / h or G / h, for bolts, nuts and other refined fastener threads, the standard is recommended to use 6H / 6g.

Medium precision grade for normal threads

Nut: 6H Bolt: 6g

Medium precision grade of thread with thick overlay

Nut: 6G bolt: 6e

High precision level

Nut: 4H bolt: 4h, 6h

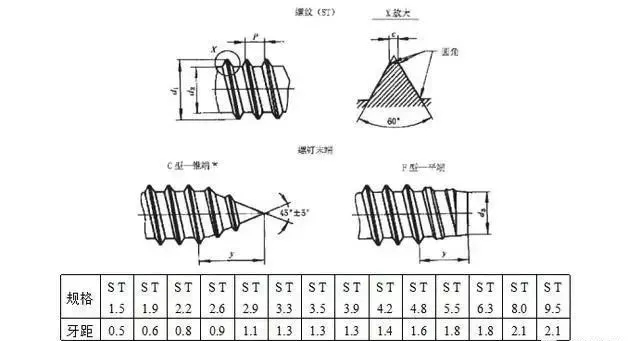

9. Common special thread

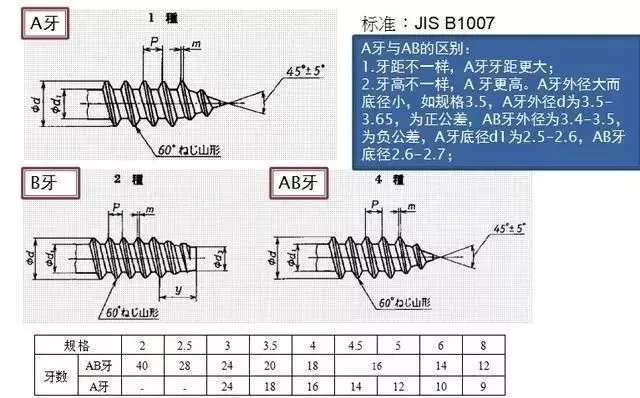

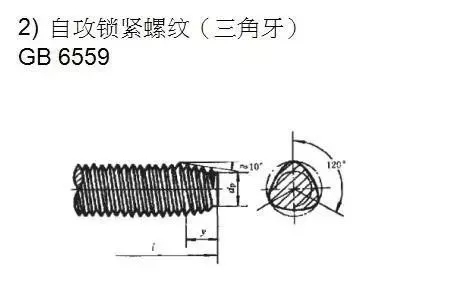

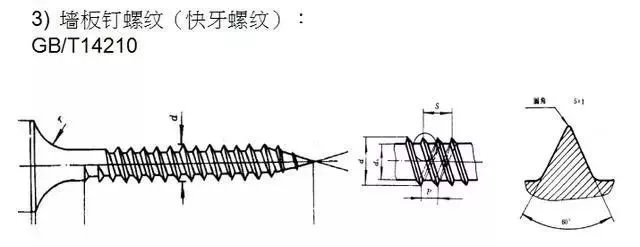

Self-tapping thread: It is a wide thread with a large lead;

GB/T5280 JIS B1007

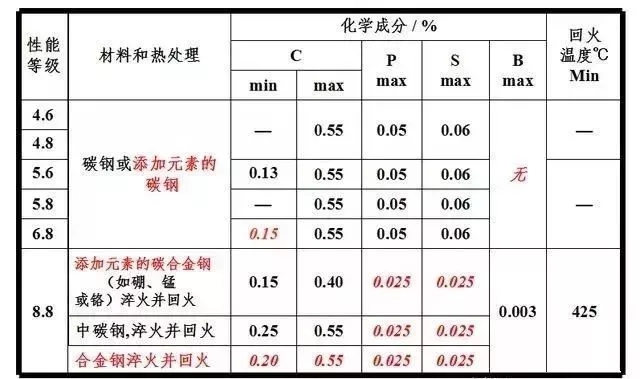

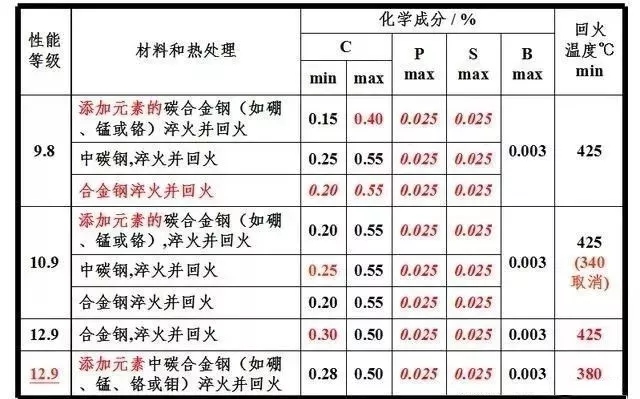

Third, the material requirements, heat treatment requirements and mechanical properties of bolts, screws and studs

Material requirements for bolts, screws and studs

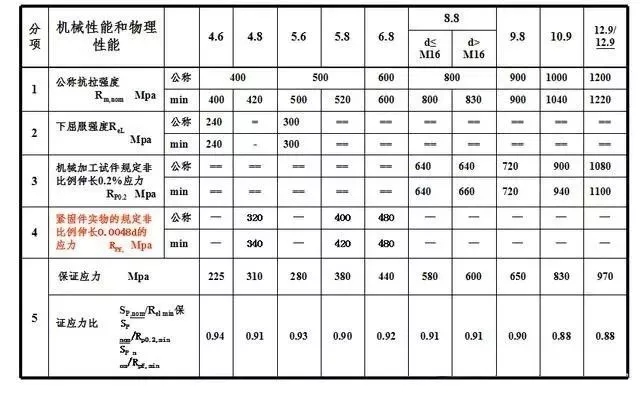

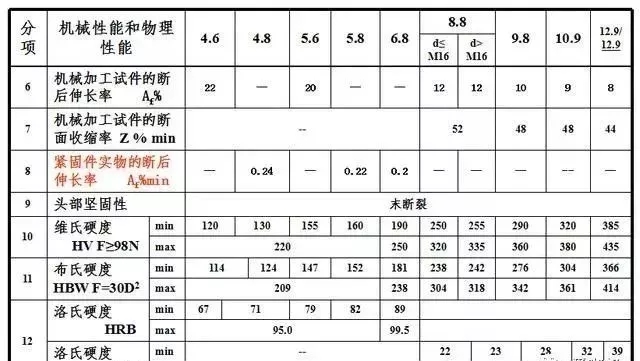

Mechanical and physical properties of bolts, screws and studs

Fourth, the type and structure of steel structural bolts

Steel structure bolting overview

A bolt connecting for steel structure is a method of connecting two or more steel structural parts or members by bolting. Bolted connections are the easiest way to connect components and structural installations.

The picture above shows the full bolt connection of the beam-column joint

Bolted joints were first used in metal construction. In the late 1930s, bolted joints were gradually replaced by rivet joints and were used as temporary fixing measures only in component assembly. High-strength bolting methods emerged in the 1950s. High-strength bolts are made of medium carbon steel or medium carbon alloy steel, and their strength is 2 to 3 times higher than that of ordinary bolts. High-strength bolted joints have the advantages of convenient construction, safety and reliability. After the 1960s, they began to be applied in the manufacture and installation of steel structures in some metallurgical plants.

The picture above shows the full bolt connection of the beam splicing

2 bolt specifications

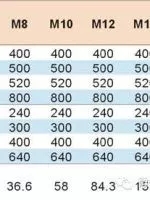

The bolts commonly used in steel structures are M12, M16, M20, M24, M30, M is the bolt symbol, and the number is the nominal diameter.

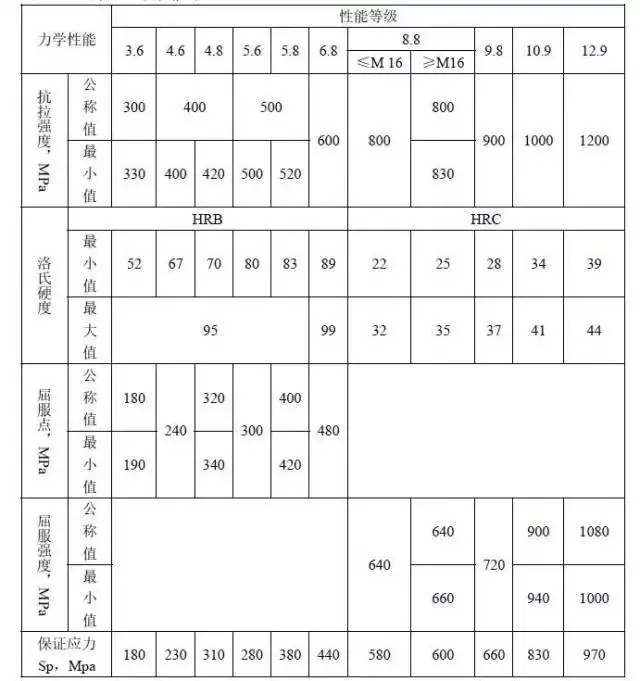

Bolts are divided into ten grades according to performance grades: 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, 9.8, 10.9, 12.9. The bolts of grade 8.8 or higher are made of low carbon alloy steel or medium carbon steel and heat treated (quenched, Tempered), commonly known as high-strength bolts, below 8.8 (excluding 8.8, refined ordinary bolts also contain 8.8) is commonly known as ordinary bolts. The table below shows the performance class and mechanical properties of the bolts.

The bolt performance grade label consists of two parts, which represent the nominal tensile strength of the bolt and the yield ratio of the material. For example, the performance grade is 4.6 bolts. The meaning of the first part number ("4" in 4.6) is 1/100 of the nominal tensile strength (N/mm2) of the bolt material, which means fu≥400N/mm2; Part of the number ("6" in 4.6) is 10 times the yield ratio of the bolt material, which means fy / fu = 0.6; the product of the two parts (4 × 6 = "24") is the nominal yield point of the bolt material ( Or 1/10 of (N/mm2) of the yield strength, that is, fy≥240N/mm2.

Steel structure ordinary bolts can be divided into three grades of A, B and C according to the production precision. Grades A and B are refined bolts, generally used for mechanical products, and grade C is thick bolts. Unless otherwise specified, ordinary steel bolts are generally ordinary C-class bolts with a performance rating of 4.6 or 4.8.

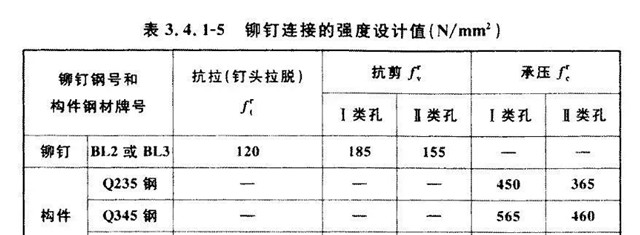

The bolt strength design value is in accordance with Table 3.4.1-4 of GB50017-2003 "Steel Structure Design Specification".

3 classification of bolts

There are many types of bolts, such as screws, bolts, standard parts, fasteners, etc.

In general, bolts include ordinary bolts, high-strength bolts, anchor bolts, expansion bolts, chemical anchor bolts, screws, studs, etc.; bolts in the narrow sense are divided into ordinary bolt joints and high-strength bolts.

(1) Ordinary bolt connection

Ordinary bolts are divided into rough bolts and refined bolts according to the production precision.

Ordinary bolts can be divided into hexagon bolts, stud bolts, countersunk bolts, etc. according to the form;

The picture above is a countersunk bolt

1) Rough bolt

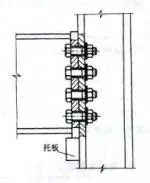

C-class bolts are generally thick bolts made of carbon structural steel. In order to make the bolts penetrate the screw holes smoothly, the hole diameter should be 1.0-2.0 mm larger than the nominal diameter d of the bolts, which is a type II hole. The bolt holes are arranged so that the wrench can tighten the nut. When the thick bolts are used for the connection of members of columns, beams and trusses, the connection structure of the pallets should be adopted. At this time, the bolt is in the tension state, and the shearing force is received by the pallet (as shown below).

The strength of the material used for the rough bolt is low, which limits its use in structural connection, but it is still obtained in the connection of the secondary beam, the wall beam, the roof beam and the support and hinged support of the working platform with small shear force. widely used.

The picture above shows the ordinary bolt

The thick bolts are also commonly used for pre-assembly of steel structures in factories, pre-tightening before riveting of riveted members, and assembly before high-strength bolting and temporary tightening before welding of mounting nodes. When the rough bolt is used as a permanent fixing bolt, it needs to be tightened after the alignment and take measures to prevent loosening.

The figure above shows the double nut anti-loose measures for the column bolts.

2) Refined bolts

The A-class and B-class bolts are refined bolts. The holes are generally Class I holes, and the hole diameter should be 0.3-0.5 mm larger than the bolt nominal diameter d. Refined bolted connections are used for structural connections that are often disassembled and riveted. Refined bolts are generally used in mechanical products and are rarely used in construction steel structures.

(2) High-strength bolted connection

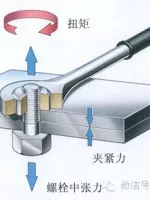

Bolts made of high-strength steel, or which require a large preload, can be called high-strength bolts. High-strength bolts apply pre-tension and transmit external forces by friction. Ordinary bolt connection relies on the shearing of the bolt and the pressure of the hole wall to transmit the shear force. When the nut is tightened, the pre-tension is small, and the influence is negligible. However, the high-strength bolt not only has a high material strength, but also exerts a large bolt. The pre-tensioning force causes a pressing force between the connecting members, so that a large frictional force is perpendicular to the screw direction, and the pre-tensioning force, the anti-slip coefficient and the type of the steel directly affect the bearing capacity of the high-strength bolt.

The picture above shows how high-strength bolts work.

High-strength bolts are mainly divided into two types according to their stress conditions: friction type and pressure type.

High-strength bolts are divided into two types according to the construction process: torsional shear type high-strength bolts and large hexagonal high-strength bolts.

The above picture is a torsional shear type high strength bolt and a large hexagonal high strength bolt

1) Friction type high-strength bolt connection, the external force is transmitted by the frictional force generated by the bolt contact pressure on the contact surface of the steel plate. After the surface of the component is sandblasted to form a red rust surface, a large friction coefficient can be obtained, and the number of connecting bolts can be reduced. The diameter of the friction type high-strength bolt should be 1.5 to 2.0 mm larger than the nominal diameter d of the bolt.

2) Pressure-type high-strength bolt connection is to transmit the stress caused by the friction between the components and the shearing force of the central shaft of the bolt and the bearing pressure of the member. The diameter of the bolt should be 1.0-1.5mm larger than the nominal diameter d of the bolt. . The hole is made by CNC drilling and drilling.

In short, friction-type high-strength bolts and pressure-bearing high-strength bolts are actually the same type of bolt, except that the design considers slippage. In design, the friction surface of the friction type high-strength bolt cannot slide, and the screw does not bear the shear force. Once the friction surface slips, it is considered to reach the design failure state, which is technically mature and reliable; the pressure-type high-strength bolt friction surface can slide, the screw It also withstands shear forces and the ultimate damage is the same as normal bolt damage (bolt cut or steel plate crush).

3) Large hexagonal high-strength bolts consisting of a high-strength bolt, a nut and two washers to form a high-strength bolted joint.

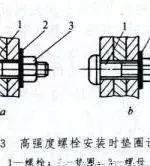

The figure above shows the gasket configuration of large hexagonal high-strength bolts and torsion-shear high-strength bolts.

During construction, the structure is temporarily fixed with thick bolts. After the structural installation is corrected, the rough bolts are replaced with high-strength bolts one by one from the middle of the bolt group and the initial tightening is performed. And the final screw.

The above picture is a large hexagonal high-strength bolt connection pair of different lengths.

When installing a large hexagonal high-strength bolt connection, a washer should be added to each side of the bolt (Fig. 3a). The initial tightening torque value is 50% of the final tightening torque value, the double tightening torque value is equal to the final tightening torque value, and the final tightening torque value is calculated as: Tc=K*Pc*d. Where Tc is the final torque value, N·m; K is the torque coefficient; Pc is the construction pre-tension, kN; d is the high-strength bolt thread diameter, mm. Use a torque wrench to apply torque correction before each use.

The picture above is a manual large hexagonal torque wrench

The picture above is an electric large hexagonal torque wrench

4) Torsional shear type high-strength bolt, a high-strength bolt, a nut and a washer constitute a torsion-shear type high-strength bolt connection pair.

The above picture is a torsional shear type high strength bolt

The picture above is a torsion type electric wrench

The picture above shows the principle of torsion-cut high-strength bolt installation.

When installing a torsion-shear type high-strength bolt connection, install a washer on the side of the nut only (Fig. 3b). The initial torque value is calculated as: Tc=0.065*Pc*d. Where Tc is the initial tightening torque value, N·m; Pc is the construction pre-tension, kN; d is the high-strength bolt thread diameter, mm. Finally, use a special wrench to twist the tail plum head. The focus of quality inspection should be placed on the supervision and inspection of the construction process.

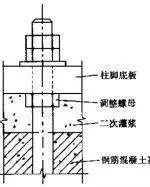

(3) Anchor bolts

The anchor bolts are aliased to the ground bolts, the ground screws, the grounding wires, etc., and are used for connecting the steel structure column legs with the concrete foundation. Generally made of Q235, Q345 round steel.

The above picture shows different kinds of anchor bolts (the anchor plate should be used with a diameter larger than 24mm)

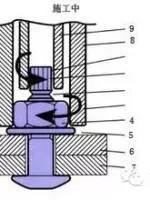

During installation, the anchor bolt group is fixed by a steel frame, installed together with the lacing cage, and then the concrete is poured, and the bolt head should expose a certain length of the concrete surface. After the concrete reaches a certain strength, the steel column foot is installed, and finally the bottom of the column is filled twice.

The picture above shows the steel frame fixed anchor bolt group

The picture above is a schematic diagram of the anchor bolt

The picture above is a picture of the steel structure column foot before secondary grouting (to protect the top of the anchor bolt from the rubber sleeve)

(4) Chemical anchor

Chemical anchors are a new type of fastening material consisting of chemical agents and metal rods. A connector for mounting other structures on an existing concrete structure. It can be used for post-embedded parts installation in various steel structures, curtain walls and marble dry-hanging constructions. It can also be used for equipment installation, highway, bridge guardrail installation, building reinforcement and other occasions.

The picture above shows the screw and medicament of the chemical anchor.

The chemical anchor bolt is a new type of anchor bolt which appears after the expansion anchor bolt. It is fixed by a special chemical bonding agent, and the screw is fixed in the bore of the crucible substrate to realize the composite member anchored to the fixing member. Because the chemical anchor bolt has a large uplift bearing capacity, it can replace the embedded anchorage. It is often forgotten to install the steel structure embedded parts at the construction site, but the concrete has been poured, and the chemical anchor embedded parts are used to remedy.

The figure above shows the bearing capacity of chemical anchors of different diameters (slightly different from different manufacturers)

The construction steps of the chemical anchor are as follows:

1) According to the engineering design requirements, drilling holes in the corresponding position in the substrate (such as concrete), the hole diameter, hole depth and bolt diameter should be determined by professional technicians or field tests.

2) Drilling with a hammer drill or a water drill.

3) Use a special air pump, brush or compressed air machine to clean the dust in the drill hole. It is recommended to repeat it no less than 3 times. There should be no dust or clear water in the hole.

4) Ensure that the surface of the bolt is clean, dry and free of oil.

5) Confirm that the glass tube anchor bag has no abnormality such as appearance damage and solidification of the drug, and put the round head outward into the anchor hole and push it to the bottom of the hole.

6) Use the electric drill and the special installation fixture to insert the screw into the bottom of the hole with strong rotation. The impact method should not be used.

7) When screwing to the bottom of the hole or the position on the bolt, stop the rotation immediately, remove the mounting fixture, and avoid the disturbance before the gel is fully cured. The overtime rotation causes the glue to drain and affects the anchoring force. (The rotation time should not exceed 30 seconds, the rotation speed should not be lower than 300 rpm, no more than 750 rpm, the bolt advance speed is about 2 cm / sec, and the impact method is not allowed.)

(5) Expansion bolt

The expansion bolt acts the same as the chemical anchor for the less stressed anchor.

The different sizes of expansion bolts in the above picture

Expansion joints shall not be used in areas where concrete structures have cracks and where cracks are likely to occur. At the same time, the main load-bearing structure, important pipelines, and expansion bolts designed for high-speed operation, subjected to impact loads and large vibrations should be selected according to the calculated design tensile strength and design shear resistance.

4 bolt arrangement and construction requirements

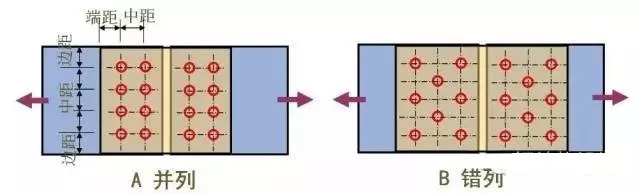

The bolt arrangement is divided into two types: parallel and staggered:

Parallel - simple, neat, compact, the connecting plate used is small in size, but the cross-section of the member is weakened;

Staggered - the arrangement is not compact, the connecting plate used is large in size, but the cross section of the member is weakened;

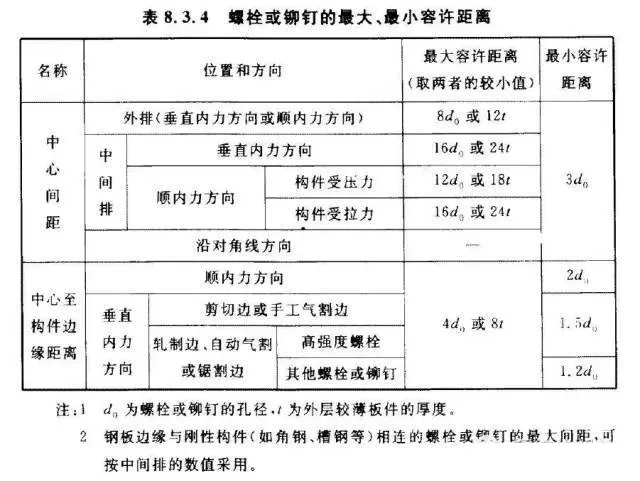

(1) Stress requirements

Vertical direction of force: In order to prevent the stress concentration of bolts from affecting each other, and the section is weakened too much to reduce the bearing capacity, the margin and end distance of the bolts should not be too small;

Direction of the direction of the force: In order to prevent the plate from being broken or cut, the end distance cannot be too small;

For the pressure-receiving member: in order to prevent the connecting plate from being bulged, the intermediate distance cannot be too large.

(2) Construction requirements

The margin and the intermediate distance of the bolts should not be too large, so as to prevent the plates from being intimately bonded and the moisture invading the corrosion steel.

(3) Construction requirements

In order to facilitate the tightening of the nut by the wrench, the bolt spacing should be no less than 3do;

According to the above requirements, GB50017-2017 "Steel Structure Design Specification" gives the allowable spacing of bolts and related design values.

Disclaimer: This article has been collected and compiled from the Internet. The copyright belongs to the original author. If you infringe on your rights, please contact us.